HVAC Systems: The Ultimate Tool for Temperature Regulation in Cannabis Cultivation

Introduction

Contents

Maintaining ideal temperatures is crucial for successful cannabis cultivation, as even minor fluctuations can greatly impact the growth and quality of the plants. One effective way to regulate temperature in a cannabis grow facility is through using an HVAC (heating, ventilation, and air conditioning) system. HVAC systems help to maintain a stable climate, control humidity levels, and prevent the spread of pests and diseases. In this article, we will explore the importance of temperature regulation in cannabis cultivation, why HVAC systems are necessary, and how to choose, set up, and maintain an HVAC system for your cannabis grow space. We will also discuss common challenges and issues that growers may face when using an HVAC system and provide tips for avoiding mistakes and developing a backup plan.

The Importance of Temperature Regulation in Cannabis Cultivation

One of the most critical factors in cannabis cultivation is temperature regulation. Temperature directly influences plant growth, development, and overall quality of the cannabis yield. A minor fluctuation in temperature can quickly disrupt the entire growth cycle and damage the plants. Consistent and optimal temperatures must be maintained throughout the cultivation process.

Extreme heat or cold can cause significant stress on cannabis plants, leading to a host of issues such as slower growth, root problems, nutrient deficiencies, insect infestations, and even complete crop failure. For instance, high temperature can cause the plants to wilt and lose their color, while low temperatures can slow their growth and cause discoloration. Temperature also impacts terpene and cannabinoid production, which directly affects the potency and flavor of the final product.

Maintaining consistent temperature and humidity levels is crucial for a successful yield. Temperature regulation is especially crucial during the vegetative and flowering stages, which are the most important phases of the growth cycle. During these stages, cannabis plants require different temperature and humidity levels, which can be achieved through a properly installed HVAC system.

In addition to temperature regulation, humidity levels also require close monitoring and control. High humidity can cause mold, mildew, and other fungal diseases, while low humidity can dry out the plants and stunt their growth. A well-designed HVAC system can help maintain both temperature and humidity levels, creating the perfect environment for cannabis cultivation.

Temperature regulation is one of the most critical factors in cannabis cultivation, and a reliable HVAC system is necessary in maintaining the optimal conditions for growth and development. The following section will cover the factors to consider when selecting an HVAC system for cannabis cultivation.

| Impact of Temperature on Cannabis Plants | Importance of Temperature Regulation |

| • Slower growth | • Consistent and optimal temperature levels are required throughout the cultivation process |

| • Root problems | • Extreme heat or cold can cause significant stress on cannabis plants |

| • Nutrient deficiencies | • Temperature impacts terpene and cannabinoid production, which affects potency and flavor |

| • Insect infestations | • Crucial during the vegetative and flowering stages of the growth cycle |

| • Complete crop failure | • Humidity levels also require close monitoring and control |

Why HVAC Systems are Necessary for Maintaining Optimal Temperatures

Maintaining the proper temperature is crucial to the success of a cannabis cultivation facility. Temperature fluctuations in a grow room can lead to stunted growth, mold, pests, and decreased yields. This is where HVAC systems come in.

HVAC systems are necessary for maintaining optimal temperatures in a cannabis cultivation facility for several reasons:

- Consistency: HVAC systems provide consistent temperature control, which is essential for optimal plant growth. Without consistency, plants can experience stress and reduced growth rates.

- Precision: HVAC systems can be programmed to maintain the exact temperature and humidity levels needed for successful cannabis cultivation. This precision ensures the best possible environment for plant growth.

- Efficiency: HVAC systems can help reduce energy costs by only running when necessary. The use of energy-efficient units can also make a big difference in reducing overall energy consumption and cost.

- Protection: HVAC systems help protect cannabis plants from extreme temperatures, which can cause damage or even death to the plant. This protection is especially important during hot summers or cold winters.

- Cleanliness: HVAC systems come equipped with air filters that remove dust and mold from the air. This helps keep the grow room clean and prevents the spread of contaminants that can harm the plants.

HVAC systems are an essential investment for any cannabis cultivation facility. They provide the necessary consistency, precision, efficiency, protection, and cleanliness required for successful plant growth.

Choosing the Right HVAC System

As you begin your journey in cannabis cultivation, it is vital to consider how temperature regulation can impact the growth and quality of your plants. In order to maintain optimal temperatures, investing in a high-quality HVAC system is essential. However, with a vast array of options on the market, choosing the right HVAC system can be a daunting task. This section will guide you through the factors to consider when selecting an HVAC system for cannabis cultivation, the different types of HVAC systems available, as well as cost considerations to help you make an informed decision.

Factors to Consider When Selecting an HVAC System for Cannabis Cultivation

When selecting an HVAC system for cannabis cultivation, there are several factors to consider to ensure optimal growth and maximum yield. These factors include:

- Size of cultivation facility: The size of your facility will determine the appropriate size of the HVAC system you need. It is important to get a system that is neither too small nor too large for your space.

- Type of cannabis: Different strains of cannabis have varying environmental requirements, including temperature and humidity levels. It is important to choose an HVAC system that can accommodate the specific needs of the strains you plan to grow.

- Operating cost: The cost of operating an HVAC system can vary widely based on the type of system, the size of your facility, and the local utility rates. It is important to consider the overall cost of operating the system over time, including energy consumption and maintenance costs.

- Environmental impact: The environmental impact of your HVAC system should also be considered, including factors like energy efficiency and emissions.

- Control and automation: Modern HVAC systems offer advanced control and automation features that can help you optimize temperature and humidity levels in your facility. Look for a system that offers intuitive controls and remote monitoring capabilities.

Taking these factors into consideration can help you choose the best HVAC system for your cannabis cultivation facility. Investing in the right system can help ensure optimal growth and a high-quality yield, while minimizing energy consumption and operating costs.

Types of HVAC Systems Suitable for Cannabis Cultivation

When it comes to choosing the right HVAC system for your cannabis cultivation facility, you have several options to consider. Each type of HVAC system has its benefits and drawbacks, so it’s important to evaluate your needs and choose the system that makes the most sense for your operation.

1. Split HVAC System

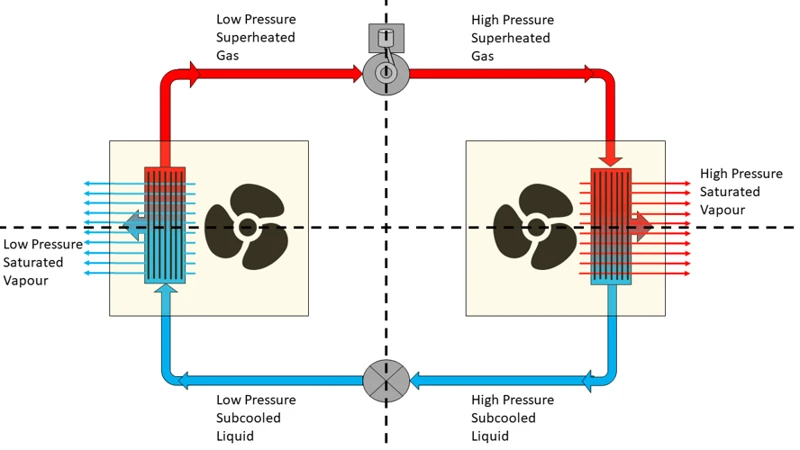

A split HVAC system is a popular choice for cannabis cultivation facilities. This type of system consists of two units: an indoor unit that contains the evaporator coil, and an outdoor unit that contains the compressor and condenser coil. Split systems are typically less expensive than other types of HVAC systems and are relatively easy to install.

2. Packaged HVAC System

A packaged HVAC system is an all-in-one unit that contains both the heating and cooling components. This type of system is generally more expensive than a split system, but it is often more efficient and can be a good option for larger facilities.

3. Ductless Mini-Split System

A ductless mini-split system is similar to a split system, but it does not require ductwork to distribute heating and cooling. This can be beneficial for cannabis cultivation facilities because ductwork can harbor mold and other contaminants that could affect plant growth.

4. Geothermal HVAC System

A geothermal HVAC system uses the earth’s natural temperature to heat and cool a building. This system can be expensive to install, but it is highly efficient and can save money on energy costs in the long run.

5. Chilled Water System

A chilled water system uses water to cool a building instead of refrigerant. This type of system can be efficient and effective, but it can also be expensive to install and require a significant amount of maintenance.

Ultimately, the type of HVAC system you choose will depend on your specific needs and budget. It’s important to consider factors like energy efficiency, maintenance requirements, and initial installation costs when making your decision. A qualified HVAC contractor can help you evaluate your options and choose the system that will work best for your cannabis cultivation facility.

| HVAC System Type | Benefits | Drawbacks |

|---|---|---|

| Split HVAC System | Less expensive, easy to install | May not be suitable for larger facilities |

| Packaged HVAC System | All-in-one unit, more efficient | Expensive, can be difficult to install |

| Ductless Mini-Split System | No ductwork required, can prevent mold growth | May not be suitable for larger facilities |

| Geothermal HVAC System | Highly efficient, can save on energy costs in the long run | Expensive to install |

| Chilled Water System | Efficient, effective | Expensive to install, requires significant maintenance |

Cost Considerations and Budgeting for an HVAC System

Cost Considerations and Budgeting for an HVAC System

When considering investing in an HVAC system for your cannabis cultivation facility, it’s important to take into account the initial cost of the system, as well as the ongoing expenses for maintenance and operation. Here are some factors to think about when budgeting for an HVAC system:

| Factor | Considerations |

|---|---|

| Size of your facility | The larger your facility, the more powerful and expensive your HVAC system will need to be. |

| Climate | If you’re in a region with extreme temperatures, you may need a more robust system to maintain optimal temperatures. |

| Type of HVAC system | Different types of systems have different initial costs and ongoing expenses. Research your options to find the most cost-effective solution for your needs. |

| Energy efficiency | Investing in an energy-efficient HVAC system may have higher upfront costs, but it can save you money over time through reduced operating costs. |

| Maintenance costs | Regular maintenance and repairs can ensure the longevity and effectiveness of your HVAC system, but it’s important to budget for these expenses. |

| Installation costs | Professional installation can be expensive, but it’s worth considering to ensure that your system is installed correctly and operates efficiently. |

It’s a good idea to consult with HVAC professionals to get cost estimates and recommendations based on your specific needs. While investing in an HVAC system may require an upfront investment, it can ultimately pay off through optimal growing conditions and increased yields. When planning your budget, be sure to account for ongoing expenses as well to keep your system in top working order.

Setting Up and Using Your HVAC System

Now that you have chosen the right HVAC system for your cannabis cultivation facility, it’s time to set it up and start using it. This step is essential to ensure that your plants grow at optimal temperatures and are healthy throughout their growth cycles. Proper installation of the HVAC system, along with the correct settings and maintenance, will help you maintain a stable climate, prevent mold and disease, and increase overall yield. In this section, we will explore the critical steps for setting up and using your HVAC system effectively. So, let’s dive in and learn how to use an HVAC system to regulate temperature fluctuations and create the optimal growing conditions for your cannabis plants.

Installation of HVAC Systems in a Cannabis Cultivation Facility

Installing an HVAC system in a cannabis cultivation facility is a critical step in ensuring optimal plant growth and yield. The installation process can be complex, and it’s essential to have a professional HVAC contractor to handle the job. Here are some key considerations to keep in mind during the installation process:

| Consideration | Explanation |

|---|---|

| Size and Capacity | The size and capacity of the HVAC system must be appropriate for the size of the cultivation facility. It’s important to ensure that the system can handle the heat load generated by the grow lights and other equipment. A professional contractor can help determine the appropriate size and capacity based on the facility’s square footage, lighting system, and the number of plants being grown. |

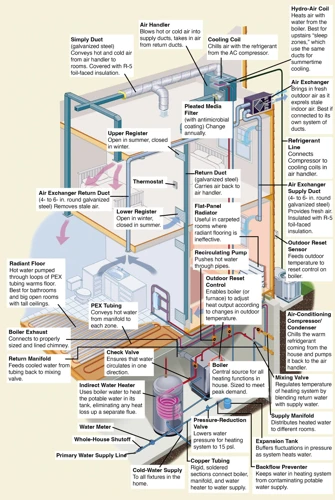

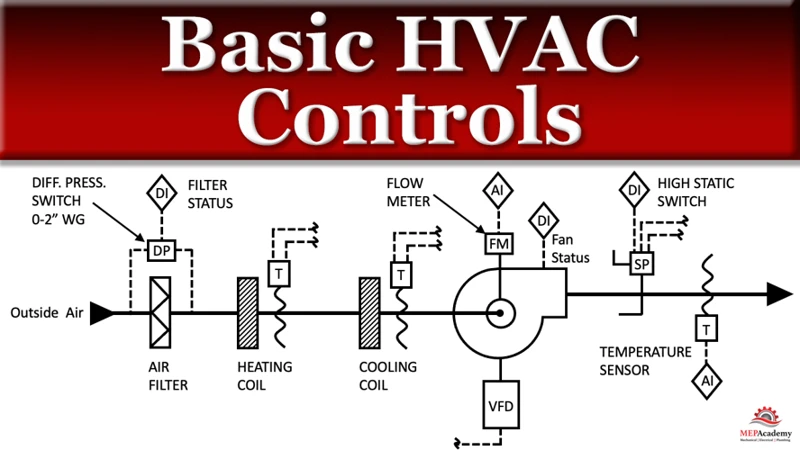

| Ventilation | Proper ventilation is crucial for maintaining healthy plants and optimal temperatures. The HVAC system should be designed to provide sufficient airflow throughout the cultivation facility, ensuring that CO2 levels remain consistent and preventing the buildup of mold and other harmful pathogens. It’s essential to ensure that air is being exchanged at the right rate, and that fresh air is being brought in from outside the facility. |

| Humidity Control | Cannabis plants require specific humidity levels during different stages of growth. The HVAC system should be equipped with humidity sensors to help regulate humidity levels in the facility. This can help prevent mold and mildew growth, as well as ensuring that plant growth is not stunted by overly dry or humid conditions. |

| Zoning | A well-designed HVAC system should include zoning capabilities, allowing different areas of the facility to be regulated separately. This can be particularly important for facilities with multiple grow rooms. Zoning allows for greater control over temperature and humidity levels, while also optimizing energy efficiency. |

The installation of an HVAC system in a cannabis cultivation facility is a complex process that requires careful planning and execution. By working with a professional HVAC contractor and considering these key factors, growers can ensure that their facility is set up for success and that their plants are provided with the optimal growing conditions.

Optimizing HVAC System Settings for Cannabis Growth

When setting up an HVAC system for cannabis cultivation, it’s important to optimize the system’s settings to ensure the best possible growth for your plants. Here are some steps you can follow to optimize your HVAC system for cannabis growth:

- Maintain the right temperature: Cannabis plants thrive in temperatures between 65°F and 80°F. You should set your HVAC system to maintain a consistent temperature within this range.

- Control humidity: While humidity levels can vary depending on the stage of growth, generally, cannabis plants grow well in a relative humidity (RH) range of 40-60%. An HVAC system with a dehumidifier can lower humidity levels, and a humidifier can increase them.

- Ensure good air circulation: Proper air circulation is crucial for cannabis growth, as it helps distribute heat and CO2 throughout the plant canopy. Place your HVAC system’s vents strategically to ensure adequate air circulation throughout the room.

- Monitor CO2 levels: CO2 is essential for cannabis growth, and HVAC systems can be used to distribute CO2 throughout the grow room. Monitor CO2 levels with a sensor, and adjust the HVAC system as needed to maintain a consistent level of around 1000 ppm.

- Adjust your HVAC system’s settings: Different stages of growth require different temperature and humidity levels; therefore, you must adjust your HVAC system’s settings accordingly. For example, during the vegetative stage, you might set the temperature to 75°F and the humidity to 60% RH, while during the flowering stage, you might reduce the humidity to 40% RH.

By optimizing your HVAC system for cannabis growth, you can create an ideal environment for your plants to thrive, resulting in higher yields and better-quality buds.

Monitoring and Maintaining Your HVAC System

Maintaining and monitoring your HVAC system is crucial for optimizing cannabis growth and ensuring the longevity of your equipment. Regular maintenance can prevent breakdowns and reduce energy costs, while monitoring can detect problems before they become major issues.

To help with HVAC system maintenance and monitoring, consider creating a schedule and checklist. Here are some items to include in your checklist:

| Task | Frequency | Description |

|---|---|---|

| Inspect air filters | Monthly | Dirty filters can reduce airflow and decrease energy efficiency. Replace or clean the filters as necessary. |

| Check refrigerant levels | Annually | Low refrigerant levels can cause the system to work harder and consume more energy. Have a professional technician check and recharge the system as needed. |

| Inspect ductwork | Annually | Check for leaks or damage that may reduce system efficiency or affect air quality. |

| Clean coils and blower wheels | Annually | Dirty coils and blower wheels can reduce airflow and decrease system efficiency. Have a professional technician clean them as needed. |

| Check thermostat settings | Annually | Verify that the thermostat is working correctly and set to the desired temperature. Replace batteries as necessary. |

| Calibrate sensors | Annually | For precise temperature and humidity control, sensors should be calibrated annually by a professional technician. |

Regular maintenance tasks should not be overlooked, as they can prevent small problems from escalating into larger, more expensive issues. If a problem does occur, taking immediate action can help prevent damage to the system and reduce repair costs.

In addition to routine maintenance, it’s important to regularly monitor your HVAC system’s performance. Use a temperature and humidity monitor to track conditions in your growing space and adjust settings as needed. Keep an eye out for unusual noises, odors, or performance issues, and address them promptly.

Remember that a well-maintained and properly configured HVAC system can save energy, reduce costs, and promote a healthy growing environment for your cannabis crop. Keep up with maintenance and monitoring, and be sure to address any issues that arise in a timely manner.

Common Challenges and Issues

As with any complex system, HVAC systems for cannabis cultivation can experience unexpected challenges and issues. These complications can be a major setback for the success of a cannabis cultivation facility. It is important to understand the common problems that can arise and how to avoid them. In this section, we will discuss common HVAC problems and how to fix them, avoiding common mistakes that can hinder successful cannabis growth, and creating a backup plan in case of HVAC failure. Let’s delve into these potential obstacles and how to overcome them to ensure optimal cannabis cultivation conditions.

Common HVAC Problems and How to Fix Them

Maintaining optimal temperature levels is crucial for any cannabis cultivation facility. However, using an HVAC system doesn’t necessarily guarantee flawless temperature regulation. HVAC systems can face a number of problems that can affect the efficiency and longevity of the system. Some of the most common HVAC system problems and how to fix them are as follows:

| Problem | Solution |

|---|---|

| Duct Leaks | A major HVAC problem that can lead to significant energy wastage, duct leaks can be fixed by sealing the leaks with duct sealant, foil tape, or mastic. Professional help may be required for more severe cases. |

| Dirty or Clogged Filters | Dirty filters can reduce the efficiency of an HVAC system, increase energy costs, and even cause the system to shut down. Regularly replacing or cleaning air filters is an effective solution to this common problem. |

| Thermostat Malfunction | A malfunctioning thermostat can cause the HVAC system to operate improperly, resulting in temperature fluctuations. This issue can be resolved by replacing or re-calibrating the thermostat. |

| Dirty or Faulty Coils | Dirty or faulty coils can hinder heat transfer, leading to reduced system performance and increased energy consumption. Regular maintenance, such as coil cleaning or replacement, is necessary to prevent this issue from occurring. |

| Refrigerant Leaks | If there is not enough refrigerant in the HVAC system, it may not be able to maintain optimal temperature levels. The solution to this problem is to identify the source of the leak and have it repaired by a professional HVAC technician. |

| Noise Issues | Noise issues can be caused by various factors, such as loose parts, faulty motor bearings, or dirty fan blades. Regular maintenance and inspection can help identify and resolve noise-related problems. |

It is essential for growers to monitor their HVAC system regularly to ensure it is functioning correctly. Regular maintenance, including routine inspections, cleaning, and component replacement, can help prevent these common HVAC problems from occurring. Having a backup plan for HVAC system failure is important to avoid any negative impact on cannabis growth and production.

Avoiding Common HVAC Mistakes for Successful Cannabis Cultivation

When using an HVAC system to regulate temperature fluctuations for growing cannabis, there are certain common mistakes that should be avoided in order to achieve successful cultivation. Here are some common HVAC mistakes and how to avoid them:

| Mistake | How to Avoid |

| Neglecting Regular Maintenance | Regular maintenance of your HVAC system is crucial to ensure it is running efficiently and effectively. Create a maintenance schedule for your HVAC system and stick to it, including regular ventilation system cleaning, inspection of the equipment, and filter replacement. |

| Improper Sizing of System | One of the most common mistakes is installing an HVAC system that is either too large or too small for the space it needs to cool or heat. Consult a professional to properly size your system based on the size of your cultivation facility, the number of plants, and the amount of heat generated from other sources. |

| Overreliance on HVAC System | While an HVAC system is important for temperature regulation, relying solely on it can create a number of issues. It’s important to properly insulate your facility to reduce the load on the HVAC system. You can also consider using other methods to regulate temperature, such as shade cloth or supplemental cooling and heating. |

| Poor Ventilation System Design | A properly designed ventilation system is key to ensuring that your HVAC system is running efficiently. Make sure that your ventilation system is properly designed and that it prevents hot spots, recirculating air, and other problems that may impact the efficiency of the HVAC system. |

| Inadequate Air Movement | Proper air movement is essential for temperature regulation in a cultivation facility. If the air is not moving properly, it can cause hot spots and uneven temperature distribution. Consider using fans or other methods to move air around the facility in addition to your HVAC system. |

Avoiding these common HVAC mistakes can help prevent issues and ensure a successful cannabis cultivation operation. By properly maintaining your HVAC system, sizing it appropriately, using other methods to regulate temperature, designing a good ventilation system, and ensuring appropriate air movement, you will be well on your way to optimal cannabis growth.

Creating a Backup Plan for HVAC Failure

In cannabis cultivation, HVAC systems are essential for regulating temperature fluctuations during the growth process. However, HVAC failures can occur unexpectedly and can be detrimental to the success of your grow operation. It is important to have a backup plan in place to address such failures and prevent crop loss.

Creating a Backup Plan for HVAC Failure

One way to prepare for potential HVAC failures is to have a contingency plan in place. This plan should involve proactive steps to mitigate the risks of HVAC failure and a clear course of action for addressing any issues that may arise. Below are some tips for creating a backup plan for HVAC failure.

| Tip | Description |

|---|---|

| Invest in Backup Equipment | Having backup HVAC equipment on hand can help reduce downtime in the event of a system failure. Consider investing in portable heating and cooling systems or renting backup units to keep your cultivation environment stable. |

| Regular Maintenance | Performing regular maintenance on your HVAC equipment can help prevent unexpected failures. Hire an HVAC professional to conduct routine inspections, change filters, and repair any necessary components. |

| Emergency Response Plan | Develop an emergency response plan that includes contact information for HVAC technicians who can provide assistance in a timely manner. This plan should outline the steps to take in case of HVAC failure, including who to contact and how to troubleshoot common issues. |

| Training for Staff | Train your staff on how to identify HVAC problems and perform basic troubleshooting procedures. This can help prevent minor issues from becoming major problems and can reduce downtime in case of an HVAC failure. |

| Communication Plan | Ensure that all staff members are aware of the backup plan and emergency response procedures. Regularly communicate updates and changes to the plan and encourage staff to provide feedback on how to improve it. |

By implementing these strategies, you can minimize the risks of HVAC failure and safeguard your cannabis crop. Remember to periodically review and refine your backup plan to ensure that it remains effective and up-to-date. With the right backup plan in place, you can maintain optimal growing conditions for your cannabis plants and ensure a successful harvest.

Conclusion

In conclusion, HVAC systems are a necessary investment for any cannabis cultivation facility that aims to maintain optimal temperatures and humidity levels. Temperature regulation is crucial for the successful growth and development of cannabis plants, and an HVAC system provides the necessary tools to achieve this.

When choosing an HVAC system, it is important to consider several factors, such as the size of the facility, the desired temperature and humidity ranges, and the budget. There are various HVAC systems available on the market, each with its own unique features and benefits.

Proper installation and setup of the HVAC system is essential to ensure effective temperature and humidity control. It is also important to regularly monitor and maintain the system to avoid potential issues and ensure optimal performance.

Although there may be some common challenges and issues associated with HVAC systems, such as equipment failure or incorrect settings, these can typically be addressed with careful planning and preparation. It is important to have a backup plan in place in case of HVAC system failure to prevent any negative impact on the cannabis plants.

Overall, implementing an HVAC system is a crucial investment for the success of any cannabis cultivation facility. Through careful evaluation and implementation, growers can ensure optimal environmental conditions for their plants, leading to higher yields and better quality cannabis.

Frequently Asked Questions

How does temperature affect cannabis growth?

Temperature plays a significant role in cannabis growth by affecting various physiological and metabolic processes that impact the plant’s overall health and yield. Temperature fluctuations can lead to reduced growth, lower yields, and even crop failure.

Can HVAC systems control humidity levels in cannabis cultivation facilities?

Yes, HVAC systems can help regulate humidity levels in cannabis cultivation facilities. They can adjust the amount of moisture in the air to maintain optimal humidity levels for healthy plant growth.

What is the optimal temperature range for cannabis cultivation?

The optimal temperature range for cannabis cultivation is between 68-77°F (20-25°C) during the day and 58-70°F (14-21°C) at night. However, specific strains may have slightly different temperature requirements.

Why is it essential to maintain consistent temperatures in cannabis cultivation facilities?

Maintaining consistent temperatures is important in cannabis cultivation facilities because temperature fluctuations can negatively impact plant growth and yield. Consistent temperatures provide plants with stable conditions to thrive.

What is the best HVAC system for a small-scale cannabis cultivation facility?

The best HVAC system for a small-scale cannabis cultivation facility depends on various factors such as size, location, and budget. Ductless mini-split systems or packaged terminal air conditioners (PTACs) may be suitable options for smaller facilities.

Can HVAC systems also improve air quality in cannabis cultivation facilities?

Yes, HVAC systems can improve air quality in cannabis cultivation facilities by filtering out airborne particles and contaminants, such as pollen, dust, and mold spores.

What should growers consider when selecting an HVAC system for their cultivation facility?

Growers should consider factors such as the size of the facility, location, power source, and budget when selecting an HVAC system for their cultivation facility.

How often should growers monitor their HVAC system?

Growers should monitor their HVAC system regularly to ensure proper functioning and optimal temperature and humidity levels. Depending on the system and facility, monitoring may range from daily to weekly.

What is the most common HVAC problem for cannabis cultivation facilities?

The most common HVAC problem for cannabis cultivation facilities is insufficient cooling capacity. This can result from a system that is too small or underpowered for the facility’s size or inadequate maintenance.

Can growers use alternative methods to control temperature and humidity besides HVAC systems?

Yes, growers can use alternative methods such as natural ventilation, fans, and dehumidifiers to control temperature and humidity in their cultivation facilities. However, these methods may not be as efficient or consistent as HVAC systems.